Plastic crates are used for storage of various goods and for shipping from one location to another. The goods are positioned in a crate, with or without cover, and set or stacked onto a pallet loaded onto a transportation vehicle such as truck or train car and shipped to its destination. Plastic crates provide protection of shipped and stored goods from damage or breakage and simplify the handling of goods.

Presently there are three types of containers used in the market today: wooden crates, cardboard boxes and plastic crates.

Wooden crates were the traditional tool for storage and handling in the past.

Cardboard boxes were an advanced product used for lightweight goods and are limited in their application.

Plastic crates have been available on the market for about 28 years. In recent years, plastic crates have gained significant market presence and continues to grow.

Applications of Plastic Crates

The international trend has switched towards the use of plastic crates and they are already in use for storage and shipping in a wide range of industries such as: agriculture, automotive, building and construction, clothing, electronics, food, fruit and vegetables, groceries in supermarket chains, bakeries, dairy, fisheries, freight forwarding, household goods, nurseries, pharmaceuticals, packaging, logistics, rubbers and white goods.

Today, all companies, up and down the supply chain, are demanding lower costs from each of their suppliers as competition increases. Returnable and reusable transport packaging offers not only reduced costs, but also increased efficiencies over most forms of one-way packaging.

Plastics crates are used in a wide range of applications. Some items, such as food packaging, become waste only a short time after purchase. The greatest advantage of plastic crates is that they lend themselves to be reused many times over.

Plastic Crates for the Fruits and Vegetable Industry

Plastic Crate The fruits and vegetable industry is extending its use in plastic crates. Millions of metric tons of fresh fruit and vegetables travel the roads of world every day. Using plastic crate is the one of the efficient methods of transporting them through all links of the distribution chain. Plastic crates typically travel through three segments of the fruits and vegetable industry. The field, the packaging through the distribution centres to the retail store..

Wooden creates and cardboard have still popularity amongst personal in the fruits and vegetable industry. But the need to have a high competitive edge makes farmer look for better alternatives for wood and cardboard. Plastic crates are much easier to handle than wooden crates. Plastic crates supports careful handling because of smooth surface not like the nails and splinters in wooden crates.

With some fruits and vegetable, there is a need for water resistant crate to allow it to keep fresh for longer time. Wooden crates are open and risk drying of the product and Waxing cardboard boxes prevents them from being recycled.

Circulation is necessary in the fruits and vegetable industry. In a vented plastic crates the product can live longer, thus enhances fresh delivery to the market.

Plastic crates are produced by extrusion or injected-moulding methods. The plastic crates are identical to each other and their uniformity is cost effective in stacking on a valuable floor space in a factory, in storage space or a in transportation vehicle space. Plastic crates can be easily stacked to achieve significant saving of valuable space and shipping costs.

In the fruits and vegetable industry, sometimes the pick is loaded into the crates, it stays there. The appearance of the plastic crates are also very attractive and encourages purchases right out of the crate and are cost effective in saving distributing the good into shelves.

The innovative use of folding plastic crate helps Stores compactly when not in use and easily pops open when needed. The folding plastic crate is durable, lightweight, solid and can allows air circulation if needed. The folding plastic crate has easy grip handles and is easily manoeuvred by hand.

The plastic crates are easy to clean with high pressure or washed with water while the wooden crates are subject to bacteria and fungus in present of water. They are also damaged by moist and change their strength and shape in presence of water. This makes the plastic crates more suitable to fruits and vegetable industry.

Plastic crates are strong enough to handle heavy load of fruits and vegetable unlike cardboard that is limited in its capacity to carry heavy weight.

Plastic crates provide better compatibility with automated machinery, than wooden crates or cardboard that cannot withstand the moist and the different temperature.

Plastic crates can also be stored in open areas. Sun and rain do not damage them as it would to wooden crate or cardboard.

Plastic crates can be easily cleaned and returned to the distribution network. Wooden crates contaminated with bacteria and fungus needs to be disposed. This makes them less cost effective than plastic crates.

Increasing safety and sanitary requirements for the fruits and vegetable industry handling food further encourage use of plastic crates over wooden crates. The switch to using plastic crates lowers insurance cost for personal with arm and back injuries.

Plastic crates have high UV resistant, not like wooden crates that are sensitive to changes in temperature.

Many fruits and vegetable companies prefer the use of plastic crates because of their ability to stand freezing conditions while the wooden crates were damaged when freeze. This allows the pick to be shipped in the plastic crates direct into freezers without the need to reload them on a separate container suitable for freezing.

The use of the plastic crates by hand requires steady, durable handles without nails or splinters. This makes the plastic crates better than the cardboard that is lack the durability and better than the wooden crates, that create a safety hazard to personal handling the crate or to product damaged by the nails.

Reuse of plastic crates is cost effective in purchasing costs. It eliminates endless purchases of cardboards that have a very short life span, and the need to buy wooden crates that have a higher life span but still 15 times less than the plastic crate. The empty plastic crates are nested within each other, which means they occupy less space and reduce shipping weight, providing savings in return distribution. The choice of reusable plastic crates or disposable cardboard boxes to transport perishable goods is often determined by the purchase price of the containers. But this is deceptive: When related overheads such as packing, shipping and storage are included, the actual cost can be up to four times as high.

Returnable Plastic Crates offer: real packaging material cost savings, more efficient unit loads, better use of precious warehouse space, increase profit and improve customer satisfaction all along the supply chain.

Reuse of plastic crates, contributes to prevention of global warming by reducing the use of trees for wooden boxes or the making of cardboard boxes.

Recyclable plastic crate can eliminate disposal cost that are constantly growing, especially in countries with limited resources. The use of plastic crates, increases wood resource in any country for the effective use of the wood.

Plastic Crates for Grocery Distribution

Plastic Crate Plastic2go manufacture and distribute plastic and storage containers and crates, as well as plastic milk and dairy crates, bottle crates, folding storage crates, roll-out carts and more.

The use of plastic crates is the most efficient and effective way of getting your products to market.

Plastic crates are used to store and move goods through all links of the distribution chain.

Plastic Crates are usually loaded in the first segment of the material handling process, and then stored or are shipped to a new location.

Plastic crates help protect delicate and fragile products, like produce, from the field through the warehouse or distribution centre, all the way until they reach the merchant’s shelves.

The use of plastic crates provides smooth, protective handling, good stability and excellent ventilation if needed.

In the grocery industry, Returnable Plastic Crates, commonly called RPC’s, which are rigid for outbound trips and folding for inbound trips, are now being used to transport all types of produce between growers and supermarkets all over the world. With one common footprint and six different stack heights that conform to the different produce, these plastic crates can be mixed on pallets to make more stable and efficient unit loads.

Reusing plastic crates is preferable to recycling as it uses less energy and fewer resources. Long life, multi-trip plastics packaging has become more widespread in recent years, replacing less durable and single-trip alternatives, so reducing waste. For example, in the UK alone, the major supermarkets have increased their use of returnable plastic crates for transport and display purposes four-fold from 8.5 million in 1992 to an estimated 35.8 million in 2002. Plastic crates last up to 20 years and can be recycled at the end of their useful life.

Reduced packaging waste is not the only benefit of using RPC’s instead of corrugated boxes, wooden flats, or foam polystyrene for produce. Better protection and reduced chilling time means more produce gets to market quicker and fresher than ever before. Sturdier transport packaging means fewer collapsed loads from moisture-saturated cardboard. The use of plastic crates is efficient in reducing warehouse space because they can be stacked or folded on top of each other without fear of damaging their precious unit loads.

Standard wooden crates are used for all grocery products that are not sensitive to weather or water. They cannot be used for dairy, health, beauty aids, automated meat systems or frozen food storage.

Plastic crates used in distribution and storage industries are an advanced reproduction of the traditional wooden crates.

The use of plastic crates has also increased because of awareness of global warming. Their reusable quality and recycling possibility, makes them the best option in the market today.

Plastic Crates for the Dairy Industry

Plastic Crate The dairy industry is one of the heaviest users of plastic crates.

Plastic dairy crates are strong and resilient made from high-density polyethylene, which stands up to the challenges of the industry. Cardboard boxes and wooden crates are somewhat lacking in the qualities necessary for the dairy industry.

Custom-made plastic crates can be used from the beginning to the final stage of the materials handling process, from the farmers to the display on supermarket shelves and then to the customer and finally, their kitchen, as has already been proven in some countries.

Dairy plastic crates are strong enough to handle the process that the handling and shipping of dairy products entails. Cardboard is light and subject to damage if fit with a heavy load.

Plastic crates can handle automated stacking equipment, high-pressure washing, sterilization and big temperature changes from warehouse to refrigeration. Those requirements cannot be met by wooden or cardboard crates that are sensitive to washing, cannot be incorporated into the processing line and are sensitive to temperature changes.

Plastic crates in the dairy industry are able to handle heavy loads and the rigors of loading, stacking and transportation.

Plastic crates used for the storage of bottles were designed to keep bottles clean and prevent damage to the bottles and contents while crates are stacked in transit resulting in ease of loading, stacking and storage. Plastic crates have smooth surfaces and are uniform preventing damage to contents. They eliminates dirt traps and makes cleaning easy regardless of size.

The innovative use of folding plastic crates means they can be stored compactly when not in use and easily popped open when needed. The folding plastic crate is durable, lightweight, solid and can allow air circulation if needed. The folding plastic crate has grip handles and is easily manoeuvred by hand.

Reuse of plastic crates is cost effective as it eliminates the endless purchases of cardboard or wooden boxes.

Reuse of plastic crates contributes to prevention of global warming by reducing the use of trees for wooden or cardboard boxes.

Recyclable plastic crates eliminate disposal costs that are constantly growing, especially in countries with limited resources. The use of plastic crates, increases wood resource in any country for the effective use of the wood.

Plastic Crates for the Bakery Industry

Plastic Crate In the bakery industry, large quantities of freshly baked breads, rolls and confections have created a challenge in terms of storage and shipment. This challenge has been met by the use of plastic crates. Though not especially heavy, baked goods are susceptible to damage if packed too tightly, when they come into contact with moisture and are subject to fungus and mould. Baked goods are also bulky and require lots of room with a minimum of stacking.

The solution to the challenges faced by the bakery industry is met by a plastic lightweight tray. This plastic crate can carry bulky loads, can stack without damaging the contents and lets the product packaging show through. Some of these crates are stack and nest and others are only half-nest.

Shallow plastic crates can also accommodate automated handling equipment and hand-truck delivery.

When empty, plastic crates nest to minimize the amount of storage and floor space required. When shipping the returned crates, they take up less volume due to their nesting property which also makes them cost effective. These requirements make the plastic crates advantageous over cardboards and wooden crates.

On the appearance side, the plastic crates have smooth surfaces which are easy to clean and no rough edges that can tear packaging, unlike wooden crates which have nails and splinters that will increase the probability of damage to goods.

The appearance of the plastic crates is also very attractive due to the wide colour range and embossed company logos and encourages purchases right out of the crate.

The innovative use of folding plastic crate helps store compactly when not in use and easily pops open when needed. The folding plastic crate is durable, lightweight, solid and can allow air circulation if needed. The folding plastic crate, has easy grip handles and is easily manoeuvred by hand or on a fully automated filling line.

Reuse of plastic crates is cost effective in purchasing costs. It eliminates endless purchases of cardboards.

Reuse of plastic crates, contributes to prevention of global warming by reducing the use of trees for wooden boxes or the making of cardboard boxes.

Recyclable plastic crates can eliminate disposal costs that are constantly growing, especially in countries with limited resources. The use of plastic crates increases wood resources.

Plastic crates for the Agriculture Industry

Plastic crates find increasing acceptance in the agriculture industry.

Plastic crates are strong enough to handle heavy loads of dirt and plants unlike cardboard.

Plastic crates provide better compatibility with automated nurseries, than wooden crates or cardboard that cannot withstand moisture and different temperatures.

Plastic crates can be easily stacked to achieve significant saving of valuable nursery space and shipping costs.

Plastic crates can also be stored in open areas. Sun and rain do not damage them as they would to wooden or cardboard crates.

Plastic crates are resistant to bacteria and fungi, both of which grow on wooden products and cardboard.

Plastic crates can be easily cleaned and returned to the distribution network. Cardboard cannot be reused and must be disposed. Wooden crates contaminated with bacteria and fungus need to be disposed. This makes them less cost effective than plastic crates.

Increasing safety and sanitary requirements for the agriculture industry further encourage use of plastic crates.

Plastic crates have high UV resistance, unlike cardboard and wooden crates, and many nurseries around the world are using them for seedlings and propagation trays.

On the appearance side, the plastic crates have smooth surfaces which are easy to clean and do not have rough edges that can tear packaging, unlike wooden crates that have nails and splinters that will damage goods.

The appearance of the plastic crates is also very attractive due to the wide colour range and embossed company logos which encourage purchases right out of the crate.

The innovative use of folding plastic crate helps store compactly when not in use and easily pops open when needed. The folding plastic crate is durable, lightweight, solid and can allow air circulation if needed. The folding plastic crate has easy grip handles and is easily manoeuvred by hand or on a fully automated filling line.

Reuse of plastic crates is cost effective in purchasing costs. It eliminates endless purchases of cardboards.

Reuse of plastic crates, contributes to prevention of global warming by reducing the use of trees for wooden boxes or the making of cardboard boxes.

The use of the plastic crates by hand requires steady, durable handles without nails or splinters. This makes the plastic crates better than the cardboard that lacks the durability, and better than the wooden crates that create a safety hazard to personnel handling the crates.

Recyclable plastic crates can eliminate disposal costs that are constantly growing, especially in countries with limited resources. The use of plastic crates, increases wood resource in any country.

Plastic Crates for the Fishing Industry

Plastic Crate The fishery industry is extending its use in plastic crates. The catch is transferred to plastic crates at the docks and then brought to the company’s holding tank, where they are processed. Seafood processors and wholesalers are “buying into” returnable plastic crates and are reaping the benefits with this new distribution mode for the industry.

Wooden creates have a long history of use within the fish industry, but since 2000 its use is declining and clearing the stage to the plastic crates.

Plastic crates are much easier to handle than wooden crates. Plastic crates supports careful handling because of smooth surface not like the nails and splinters in wooden crates.

Plastic crates are easy to open and close than wooden crates that are not accurate in craftsmanship.

The catch needs to stay in water therefore plastic crates are the only product that can hold water without loosing it. Not like cardboard that is not able to hold water and wood that is not water resistant. Plastic crates when full weigh 116 lb while wooden crates when full weigh 140lb, which makes the wooden crates much more expensive to ship than the plastic crates.

In some cases the plastic crates ability to float is an advantage over the wooden one since dragging the crate to shore is the transportation-referred method.

Circulation is necessary in the fishing industry and the product can live longer in a plastic crate and enhances fresh delivery to the market.

Plastic crates are produced by extrusion or injected-moulding methods. The plastic crates are identical to each other and their uniformity is cost effective in stacking on a valuable space on a boat or a ship. Plastic crates can be easily stacked to achieve significant saving of valuable space and shipping costs.

In the fishing process, once a catch is loaded into the crates, it stays there. The plastic crates don’t absorb water like wood, thus they have a consistent tare weight of 16 lb.

The plastic crates are easy to clean with high pressure or washed with water while the wooden crates are subject to bacteria and fungus in present of water. They are also damaged by moist and change their strength and shape in presence of water. This makes the plastic crates more suitable to the fishing industry

Plastic crates are strong enough to handle heavy load of fish unlike cardboard that is not suitable for the fishing industry because of constant presence of water and moist.

Plastic crates provide better compatibility with automated machinery, than wooden crates or cardboard that cannot withstand the moist and the different temperature.

Plastic crates can also be stored in open areas. Sun and rain do not damage them as it would to wooden crate or cardboard.

Plastic crates can be easily cleaned and returned to the distribution network. Wooden crates contaminated with bacteria and fungus needs to be disposed. This makes them less cost effective than plastic crates.

Increasing safety and sanitary requirements for the fishing industry handling food further encourage use of plastic crates over wooden crates. The number of arm and back injuries has been reduced substantially with the switched to the plastic crates.

Plastic crates have high UV resistant, not like wooden crates that are sensitive to temperature changes.

Many fishing companies prefer the use of plastic crates because of their ability to stand freezing conditions while the wooden crates were damaged by the extreme freezing conditions. This allows the catch to be shipped in the plastic crates direct into freezers without the need to reload them on a separate container suitable for freezing.

The use of the plastic crates by hand requires steady, durable handles without nails or splinters. This makes the plastic crates better than the cardboard that is lack the durability and better than the wooden crates, that create a safety hazard to personal handling the crate or to product damaged by the nails.

The appearance of the plastic crates are also very attractive and encourages purchases right out of the crate and are cost effective in saving distributing the good into shelves.

The innovative use of folding plastic crate helps Stores compactly when not in use and easily pops open when needed. The folding plastic crate is durable, lightweight, solid and can allows air circulation if needed. The folding plastic crate has easy grip handles and is easily manoeuvred by hand.

Reuse of plastic crates is cost effective in purchasing costs. It eliminates endless purchases of cardboards that have a very short life span in the fishing industry and the need to buy wooden crates that have a higher life span but still 15 times less than the plastic crate. The empty plastic crates are nested within each other, which means they occupy less space and reduce shipping weight, providing savings in return distribution.

Reuse of plastic crates, contributes to prevention of global warming by reducing the use of trees for wooden boxes or the making of cardboard boxes.

Recyclable plastic crate can eliminate disposal cost that are constantly growing, especially in countries with limited resources. The use of plastic crates, increases wood resource in any country for the effective use of the wood.

The William Atwood Lobster Co. is a big company using the plastic seafood crates. The company, which has the biggest shipping facility in Maine, USA sells more than 6 million lb of lobster each year .They use 4,000 plastic crates to catch, clean, sort and hold live shellfish – mainly lobster. The lobsters remain in the submerged crates from catch to the tank. After two days in the tank, they’re sorted, graded and placed in colour-coded crates according to grade. Keeping the catch submerged at all times so customers don’t buy dead lobsters.

Plastic2go Plastic Crates

Our plastic crates are a result of many years of continued and extensive research, development and use, offering a cost-effective solution to diverse storage and distribution requirements as well as offering many benefits over traditional materials, such as wood crates or cardboard boxes.

Our plastic crates require little or no cost for repair and maintenance, which reduces crates costs per trip by up to 75%, resulting in a faster return on investment.

Our plastic crates offer high dimensional stability with variation of loads, from lightweight, through medium-duty up to heavy-duty.

Our plastic crates are waterproof. They can handle different types of weather and a wide range of temperatures, from sub freezing temperature to temperatures as high as 85℃, which makes them ideal for food, pharmaceuticals, automated warehouses and or outdoor storage.

Our plastic crates are resistant to humidity and therefore are most suitable for storage and transportation of products that must stay dry, like chocolate, coffee, paper products, pharmaceuticals, exotic wooden products, cement, spices, cereal and dry minerals.

Our plastic crates are resistant to bacterial contamination under a wide range of operating temperatures. This makes them suitable for food handling, automated warehouses and outdoor storage.

Our plastic crates are moulded, which makes their stacking much more efficient inside a warehouse, in a truck and in a container. Therefore, it is cost-effective in saving storage space.

Our plastic crates weigh 30-50% less than same-dimension wooden crates. This makes them cost-effective for shipping, airfreight and storage.

Our plastic crates have no sharp edges, no nails and no splinters, so they minimise the damage to personnel and goods and are safe and easy to handle. Those qualities found to be effective in enhancing safety in the material handling industry both for workers and for products

Our plastic crates are easy to clean. You can wash them with high pressure or, if needed, sterilize them at temperatures up to 120℃.

Our plastic crates are non-absorbent and neutral to odours and tastes. This makes them suitable for pharmaceutical or food applications. This quality makes our plastic crates much more hygienic!

Our plastic crates are environmentally friendly. Reusing them reduces the chopping down of trees by replacing wooden crates or processing of wood into cardboard, thereby decreasing global warming.

Our plastic crates are 100% recyclable. When damaged, our plastic crates can be remoulded and save some more trees.

Plastic Crates vs. Wooden Crates

Plastic Crate Plastic crates have significant advantages over their wooden and cardboard counterparts.

Safety

Plastic crates are safer to handle than wooden crates, due to the design, smooth finishing and lower weight.

Plastic crates have significantly lower weight than wooden crates. Using plastic crates decreases worker compensation and insurance costs associated with back injuries from lifting.

Plastic containers have no sharp edges, no nails and no splinters. Using plastic crates lessens insurance costs associated with workers’ injuries and damage to goods.

Space savings

Plastic crates are space saving relatively to wooden crates and therefore decrease shipping and storage costs.

Plastic crates in contrast to the wooden products can be easily stacked on top of each other even outside in all weather conditions and save storage space.

A stack of ready-to-go nested Plastic crates will use less than half the space of a similar number of wooden crates. Nesting allows distribution centres to have a supply of products on hand ready for shipment.

Nestable or folding plastic crates are cheaper to transport when empty – 24% to 60% less space and weight.

Ease of use

Plastic crates are easier to handle than wooden products because of uniformity, variety of design and ease of manoeuvrability.

Uniformity of plastic crates on factory assembly lines causes fewer stoppages by size differences. Plastic crates are moulded. They are 100% identical to one another in size and allow easy calculation of measurement for shipping and storage. They are also easy to use with robots and assembly lines.

Plastic crates offer a wider variety of designs than wooden products. There are over 15.000 k kinds of crates to suit different needs, sizes and load requirements.

Plastic crates offer easy handling by hand because of durable handles.

Plastic crates are lighter than wooden crates. Therefore, Plastic crates have an advantage in manoeuvring by human hand.

Versatility

Plastic crates are more versatile than wooden crates.

Plastic crates can be used in cold and warm conditions from -22℃ to +60℃ (-40℉ to +140℉) with no damage, unlike wooden crates, which are damaged by even mild changes in temperature.

Plastic crates have a very high UV rate. They can be stored outside in rain, wind and sun, which have little to no damaging effect. Wooden crates are sensitive to the elements.

Ease of Cleaning

Plastic crates are much more hygienic than wooden crates. The hygienic properties of plastic crates are extremely important in agriculture, food and pharmaceutical industries.

Plastic crates are easy to clean with solvents, steam or water, while wooden crates are damaged in contact with solvents, steam and water. Plastic crates can be steam-cleaned with temperatures up to 120℃.

Plastic crates are not a substrate for bacteria, fungus and insect contamination, unlike wooden crates.

Plastic crates do not absorb water and are impervious to acids, fats and solvents, while wooden crates are most sensitive to acids, fats and solvents.

Durability

Due to their strength and design, plastic crates are more durable than wooden crates. The average plastic crate’s life ranges from 50 to 500 usages (depending on its type) versus 10 to 50 usages for the wooden products which then need to be repaired. That’s about ten times more durable.

Cost Efficiency

Plastic crates are much more cost-effective relative to wooden crates because of their durability. The cost of a plastic crate ranges from as low as US$2.00 up to US$60.00 with the average price about US$17. The average cost of a wooden product is about US$9. However, on a per-trip basis plastic crates are by far more cost-effective than wooden crates. The average cost per trip is about US$0.01 for a plastic crates, compared with an average of US$0.25 per trip for the wooden product.

There are other costs associated with continually purchasing wooden crates and maintaining them as opposed to plastic crates. There are also costs associated with warehousing because of damage to shipped product due to broken wooden crates or damage caused by nails or splinters. Plastic crates are durable and save cost on insurance on returned products.

Plastic crates are significantly lighter than wooden crates. Plastic crates weigh 2-4 times less than wooden crates. The lower weight of plastic crates results in savings of shipping costs, especially for air freight.

Most plastic crates are fully recyclable. This is very important issue in the time when government around the world enforce strict environmental policies and regulations. In some countries, the use of environmentally friendly plastic crate can result in significant cost savings and attract governmental support and subsidies. Plastic crates made of recycled plastic are available at a lower cost.

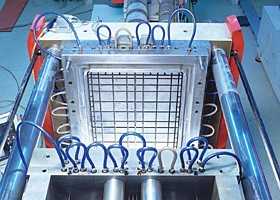

Plastic Crates Manufacturing Process

Plastic Crate Manufacturing Plastic crates have an advantage because they can be manufactured using several different technologies: high impact injection moulding, structural foam injection moulding, blow moulding, rotational moulding, single-sheet vacuum thermoforming and twin-sheet thermoforming.

The High Impact Injection Moulding process involves forcing a hot mixture of resin into a mould to make a plastic crate. Plastic crates made by the injection moulding process have many internal features such as channels and ribs to increase the strength of the crate and reduce its weight. The finished product is a solid plastic crate that is very rigid and sometimes too fragile for some applications. Injection-moulded crates have lower impact strength relative to other types of plastic crates, particularly at low temperatures.

Structural Foam Injection Moulding is similar to conventional injection moulding, except that a foaming agent is introduced with the resin melt and injected into the mould using low pressure. The result is a crate, with an integral skin and, a cellular foam core with a high strength-to-weight ratio. An advantage of structural foam is that it gives the crate some flexibility. This process also helps to keep the overall weight and material costs of this plastic crate down. This kind of plastic crate is consistent and offers good dimensional stability. It can be manufactured with post-consumer recycled material to reduce the cost. Structural foam plastic have the highest load capacity among different types of Plastic crates. They are particularly useful for heavy-duty applications.

Blow Moulding involves injecting air into the mould to blow the plastic out to the sides of the mould. The resulting crate looks like a twin-sheet thermoformed crate. Blow moulded Plastic crate have lower structural strength than other types of crates and can be used for light-weight products.

Rotational Moulding uses a large, clamshell-like mould loaded with resin in granular form. The mould spins over a heat source and the centrifugal force pushes the melted resin to the sides of the mould, creating the Plastic crate. Rotational moulding principal has an advantage because of its lower-cost tooling. However, the process is more time-consuming than others. It is not the process to use for high-volume, specialized requirements.

Vacuum Thermoforming involves a sheet of plastic that is pulled onto a mould via a vacuum process. This is one of the lower-cost methods for making Plastic crates. Tooling for vacuum forming and twin-sheet thermoforming is less expensive than for injection moulding or structural foam moulding. However, vacuum-formed crates tend to have rather thin walls, offering limited impact strength. Some manufacturers add steel rods within the plastic shell to give the crate strength.

Twin-sheet Thermoforming is similar to vacuum forming, except that two sheets of plastic are brought together. In twin-sheet thermoforming, two sheets are pulled into-the mould at the same time. The two sheets are bonded together with heat. The twin-sheet plastic crates are durable, often showing little if any damage after being hit .The disadvantage of the twin-sheet thermoformed crate is their lower dynamic load capacity comparatively to structural foam crates.

Among all of the types of plastic crates available on the market, structural crates are considered the best for major heavy-duty closed-loop applications in food distribution for storage and delivery systems.

Advantages of Plastic Crates

- Plastic CratePlastic crates are easier to handle than wooden crates.

- Plastic crates offer wider variety of designs than wooden crates.

- Plastic crates appearance is smoother, cleaner than wood. This offers the ability to sell out of the crate without the need to transfer onto shelves

- plastic crates are lighter and are safer to handle comparatively to wooden products. Lower weight of Plastic crates decreases worker compensation and insurance costs associated with back injuries from lifting crates.

- Plastic crates offer easier handling with loading by hand. Plastic crates are safer for use because of smooth design with no nails or splinters. Plastic crates usage supports a good delivery of product and is cost-effective in insurance to product delivered.

- Plastic crates in contrast to wooden counterparts can be easily stacked on top of each other and are save space.

- A stack of ready-to-go nested Plastic crates will occupy less than half the space a similar number of wooden crates might. Nesting makes it easy for distribution centres to have a supply of the crates on hand ready for shipment.

- Plastic crates can be stored outside with no damage and saves factory space.

- Plastic crates are identical to each other and comply with required specifications for dimensions, weight, and load capacity. This is a very important feature for automated material handling, storage and shipping.

- Plastic crates are easy to clean. Plastic crates are much more hygienic than wooden products. They are easy to clean with solvents, steam or water and are not a substrate for bacteria, fungus and insect contamination as is the case for wooden products.

- Plastic crates do not absorb water and are impervious to acids, fats and solvents. Hygienic properties of Plastic crates are extremely important in agriculture, food and pharmaceutical industries.

- Plastic crates provides more attractive product displays in retail application because of colour options

- Plastic crates are strong and durable. Plastic crates can withstand deep freezing conditions as well as open and extreme sun conditions.

- Plastic crate usage minimise the need for costly wood crate repairs.

- Plastic crates can not be used for firewood by employees.